WATER TREATMENT

VSLPRAYAG is associated with M/s. AQUATION EXCHANGE, Coimbatore, who are one of the leading water treatment companies in South India – with its’ operations since 2004.

We offer complete range of Water Treatment Plants such as :

A. Sea & Brackish water Desalination Plants

B. Reverse Osmosis Plants,

C. Waste & Effluent Water Treatment Plants

D. Sewage Treatment Plants

E. De-Mineralisation Plants

F. De-Alkalisers & De-Gasifiers

G. Multi Grade Filtering systems,

H. Chemical Dosing Systems

I. Domestic Purifier etc., of varying capacities

J. Water Softeners

We have supplied number of plants in India, which are working to customer’s complete satisfaction.

We offer custom built plants to suit the customer’s requirement of both quality and quantity. In addition, the company offers pre-engineered standard packaged units, some of which are available off the shelf.

The Manufacturing & assembling unit is located at Coimbatore, Tamilnadu state. It consists of well equipped fabrication workshop and in-house testing facility for complete check-up before the plant is dispatched. All the work of Process Design, Fabrication, Pre dispatch testing, Inspection, etc., is offered under-one-roof.

We engage well-qualified & experienced staff with a rich background. Our team of engineers & chemists offer technical guidance as well as prompt after sales

WATER – THE BASIS OF LIFE

Water is essential to life, irreplaceable and it is our core business. Indeed, every day we work towards the goal of providing people around the world with a sufficient supply of clean water.

|

|

As an international supplier of systems for

In combination with innovative and in-house developed processes, our know-how with regard to conventional processes and specific technologies such as:

|

Furthermore, we are one of the few companies in the world to offer the complete spectrum of technologies (LOW ENERGY Desalination processes) for the desalination of sea and brackish water. service to all our customers.

UNIQUE SELLING PROPOSITION: The company enjoys international success as a DBO (Design-Build-Operate) specialist in all water treatment related works:

Consulting & Technology Services

Project Techno Economic feasibility studies

Design & Detailed Engineering Services

Manufacturing & Supply

Erection & Commissioning´

Training & After-sales service

MINERAL WATER PLANT

We are one of the leading Mineral Water Bottling Plant manufacturers and suppliers providing excellent water treatment. Our excellent array of this plant is highly appreciated for its effective filtration of contaminated water. We ensure our clients that our mineral water plant provides bacteria free water, which is good for health.

Leveraging on our advanced and modern manufacturing facilities, we develop and offer our clients a durable range of Mineral Water Plants that are designed in compliance with the BIS guidelines. These mineral water plants comprise a pre-filtration system, reverse osmosis system, sub-micron filter, ultraviolet, ozonator and SS storage tank, which increase their ability to meet specialized needs. Due to its optimum quality and wear and tear resistance, this range is watermarked with ISI 14543 – 2004. Our range of mineral water plants is ideal for usage in processing mineral waters, soft drinks, beers and juices.

Features

The major impurities of waters can be classified into three main groups:

Non-ionic & undissolved physical impurities [Turbidity, Odour, Colour etc]

Ionic and dissolved impurities [Ca, Mg, Na, So4, Cl, iron etc]

Microbiological impurities [Bacteria, Virus, Pathogens etc]

There are various processes employed to purify the water and various combination of the processes are incorporated to ensure that final composition of the product conforms to the most stringent norms.

Typically a Mineral water Plant may consist of:

Chlorine/Hypochlorite dosing system is done in the raw water for disinfection / oxidation of iron and manganese (if present) in the water before filtration.

• Water Storage Tank:

Raw water, after chlorination, is required to be stored to achieve a detention time as per process

• Multi-Grade Sand Filter:

Sand filtration is the most frequently used, robust method to remove suspended solids from water. The Filter consists of multiple layers of sand with a variety in size and specific gravity. The Filters are designed to remove turbidity and suspended particles present in the feed water with minimum pressure drop.

• Activated Carbon Filter:

We manufacture a complete range of Activated Carbon Filters in different sizes. The Activated carbon Filters are designed to remove free chlorine, organic matter, odour and Colour present in the feed water with minimum pressure drop.

• Antiscalant Dosing System:

To prevent membrane Antiscalant dosing (scale inhibitor) system is provided.

• Micron Filters:

Micron Filtration is achieved by a series of filtration with the 10 Micron and 5 Micron Cartridge Filters.

• Reverse Osmosis System:

Reverse osmosis is the process of forcing a solvent from a region of high solute concentration through a membrane to a region of low solute concentration by applying a pressure in excess of the osmotic pressure. This is the reverse of the normal osmosis process, which is the natural movement of solvent from an area of low solute concentration

• Ultra Violet Sterilizer:

Ultraviolet light deactivates the DNA of bacteria, viruses and other pathogens and destroys their ability to multiply and cause disease. Specifically, UV light causes damage to the nucleic acid of microorganisms by forming covalent bonds between certain adjacent bases in the DNA. The formation of such bonds prevents the DNA to reproduce.

• Ozone Generator:

Though RO System rejects all the micro – organisms like bacteria & virus; may redevelop in packed bottles over a period of time. Hence, it is necessary to disinfect RO Product water prior to bottling.

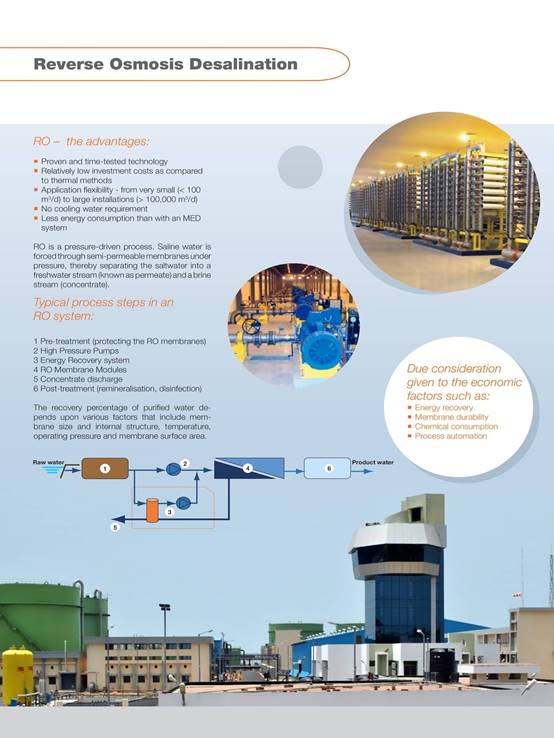

REVERSE OSMOSIS

The Reverse Osmosis systems are field proven, highly reliable and a cost effective answer to treating a wide range of brackish waters. Designed with flexibility, the series utilise state–of–the-art spiral wound reverse osmosis membranes to suit a given application. These systems can remove 90 – 98% of Total Dissolves Salts.

Ø Application

To get pure, protected drinking water in houses, Apartments, Residential Colonies, Hospitals, Clinics, Restaurants, Hotels, Industries, Schools, Colleges, etc.

Ø Process water for manufacturing plants and Boiler feed Water

Ø Beverage and Food processing industry.

Ø Mineral Water and Pharma Industry

Ø Haemodialysis Application..As a pretreatment system before Demineraliser Plant to save Cost on Control.

Ø Removal of Nitrates, Arsenic, Fluoride and other contamination from Drinking Water.

Reverse osmosis is the process of forcing a solvent from a region of high solute concentration through a membrane to a region of low solute concentration by applying a pressure in excess of the osmotic pressure. This is the reverse of the normal osmosis process, which is the natural movement of solvent from an area of low solute concentration, through a membrane, to an area of high solute concentration when no external pressure is applied. The membrane here is semipermeable, meaning it allows the passage of solvent but not of solute.

To illustrate, imagine a semi-permeable membrane with fresh water on one side and a concentrated aqueous solution on the other side. If normal osmosis takes place, the fresh water will cross the membrane to dilute the concentrated solution. In reverse osmosis, pressure is exerted on the side with the concentrated solution to force the water molecules through the membrane to the fresh water side.

The membranes used for reverse osmosis have a dense polymer barrier layer in which separation takes place. Since Reverse Osmosis does not occur naturally, it must be created by applying pressure to the high solids water in order to force it through the membrane, with pressures from 8 - 14 bar for fresh and brackish water, and 40 - 70 bar for seawater, which has around 24 bar (350 psi) natural osmotic pressure which must be overcome.

EFFLUENT AND SEWAGE TREATMENT PLANT

Effluent and Sewage Treatment Plants are used for treating effluent or sewage water to maintain the purity in water.

We have established ourselves as one of the premier manufacturers of a wide range of Effluent and Sewage Treatment Plants.

These plants are effective in discharging the effluent or sewage and also to recycle the water back for process use. Our range of effluent and sewage treatment plants helps to remove the undesirable properties present in the water like smell, color, sludge, distaste and all other harmful matter.

We have created a niche for ourselves by creating a trouble-free range of Effluent Treatment Plant. This is an asset for treating various defective portable water sources. The effluent treatment plant is designed to treat the effluent coming from different areas of the plant with the treatment of different effluents varying with the type of effluent. Our range of effluent treatment plants are designed in compliance with the State Pollution Control Board hence and are ideal for handling industrial effluent originating from all type of industries.

Applications:

• Textile processing industry

• Laundry units

• Paper industry

• All type of effluent generating industry

WATER SOFTENER PLANT

We are a renowned supplier of Water Softener Plant, which are precision engineered as per the industry standards. Our range is widely applicable in homes, Hotels, hospitals, institutes and various other places. These Water Softener Plants are highly efficient in providing softening the water and provide excellent quality water.

aquaion Industrial and Domestic Water Softener are available in a wide range with maximum flow rate from 500 to 60000 LPH. In this process, hard water is converted to soft water. The maximum permissible limit of hardness in water is 200 ppm(mg/lit). About 62% of India suffer from more than 200 ppm of hardness in water.

But what makes water hard?

Hard water contains excessive Calcium and Magnesium salts, which are harmful.

Applications:

• Home and apartments

• Process water for manufacturing plants

• Boiler feeds water and cooling water make-up

• Beverage and food processing industry

• Hospital, hotel, institute, laundries and more