Energy Management Services

OVER VIEW & INTRODUCTION OF VSLPRAYAG GROUP

VSL PRAYAG ENERGY SYSTEMS & SERVICES (VSLPRAYAG), the flagship & Energy Re-Engineering Technology arm of VSLPRAYAG Group, consisting of M/s. SAMARTH AIRTECH & M/s. ANALA PUMPS (S J INDUSTRIES) has been serving the Indian industry since 28 years. SAMARTH is involved in Manufacturing of Energy Efficient HVAC Systems & Energy Saving Products for various Electrical & Thermal Applications. All the Energy Efficient systems are manufactured at our Ahmedabad as well as Coimbatore works – our group companies. This includes State-of-the Art Automation systems for various applications (Air Conditioning, Waste Evacuation systems of Power Plants as well as Industries) with channel partnership of Siemens.

At VSLPRAYAG we facilitate Energy Cost optimisation for All Energy Consumption Centers. Our experts have more than 25 years of experience in the Energy Management in industry:

- Cement Industry

- Steel, Iron, Aluminium & Foundries

- Power Plants – Small, Medium & Large

- Textile & Textile Processing industries

- Petrochemical - Synthetic & Manmade Fiber

- Pharmaceutical & Chemical Processing etc.,

- Pulp & Paper

- Engineering, Automobile, Foundry, Metal & Metal Products

- Sugar, Distillery & Brewery

RE-ENGINEERING ENERGY SAVING POTENTIAL IN VARIOUS ELECTRICAL & THERMAL UTILITIES – IN A TYPICAL TEXTILE INDUSTRY:

Generally the following Utility Areas / Equipment offer scope for Energy Cost Optimisation in a Textile Industry through Re-Engineering:

- AHU; Humidification Plants & Ventilation System (Potential = 25 ~ 40%)

- Air Compressor & Compressed Air System (Potential = 15 ~ 30%)

- Waste Evacuation System (Potential = 15 ~ 30%)

- Boilers, Thermopacks & Steam / Thermic System (Potential = 10 ~ 20%)

- Water Treatment & Water Utilisation System

- Electrical System (Inclusive of Lighting System (Potential = 15 ~ 20%)

We take up Turn Key execution to successfully implement the identified Energy Re-Engineering Initiatives with attractive payback periods.

BENCH MARKING INNOVATIVE DEVELOPMENTS IN RE-ENGINEERING

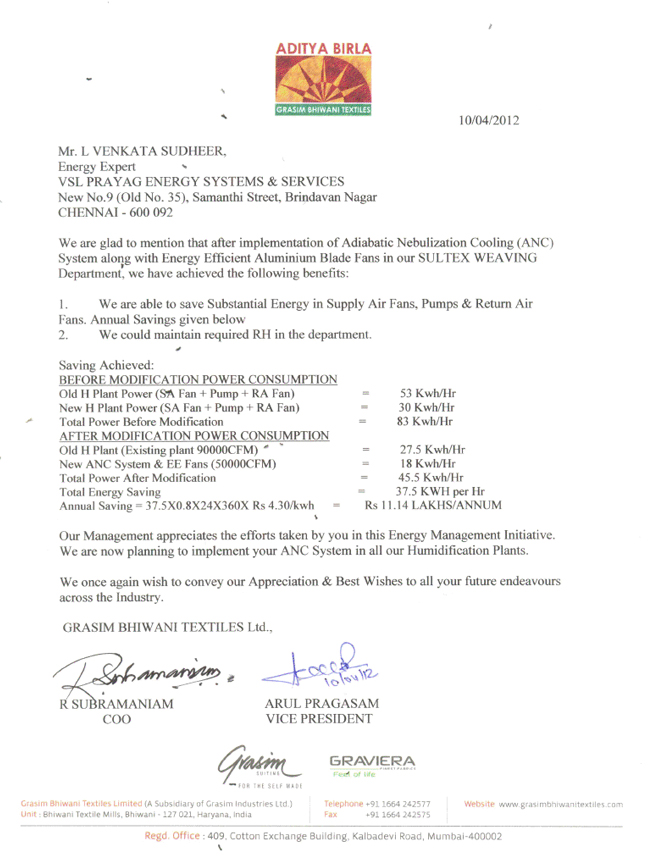

Adiabatic Atomisation Cooling System (AAC) is similar to conventional system however with latest energy efficient technologies in Air conditioning system (Re-Engineered with High Efficiency Fans (Axial flow or Centrifugal) along with Ultra Efficient Pumps developed internally). These systems can be retrofitted in any Humidification / Air Conditioning / Ventilation / Pressurisation systems installed in any type of industry or Power Plant. Recently, we have achieved benchmarking Specific Energy Consumption norms of about 7500 cfm/KW in Air Handling Units. The conventional systems mostly are found to be below 3000 cfm/kW. In addition, we generally improve department conditions.

In addition to this, we have also developed state-of-the-Art ENERGY EFFICIENT AUTOMATION SYSTEM, along with VFD Control of Supply Air & Return Air Fans as well as Pumps. It ranges from simple Semi Automation to Full-fledged SCADA systems. We employ SIEMENS Sensors & PLC for all the above mentioned Automation systems.

OUR MANUFACTURING FACILITY @ SAMARTH AIR TECH PVT LTD., AHMEDABAD

Incorporated in 1993, over the past 25 years, SAMARTH has been specialized in manufacturing of HVAC (Pressurisation & Ventilation) systems, Air handling units, Industrial (Axial & Centrifugal) fans & blowers as well as complete range of HVAC accessories such as Mist Eliminators, Distribution Louvers, Duct Diffusers, Dampers, Air Washer Spray nozzles, Rotary Dum Filters etc.,.

We have supplied our systems to number of countries across the globe – Kenya, Nigeria, South Africa, Bangladesh, Egypt, and Thailand.

We are also OEM suppliers for C Doctaire, Voltas etc., who are leading HVAC system suppliers.

Apart from HVAC systems, from our Ahmedabad works, we manufacture & supply a number of Pharma Machinery, lab scale equipment & Diary equipment.

OUR CUSTOM DESIGNED HVAC SYSTEMS FIND APPLICATION IN:

-

Cement & Steel Industries

-

Power plants – Small, Medium & Large

-

Petrochemicals & fertiliser industries

-

Process industries

-

Metallurgical industries

-

Radiators & heat exchangers

-

Boiler industries

CUSTOM DESIGNED HVAC: AIR HANDLING UNIT / PRESSURISATION / VENTILATION SYSTEM FOR:

-

Steel plants

-

Cement plants

-

Power plants

-

Electrical rooms like switchgear & bus bar rooms

-

Electrical sub stations (DG & TG control rooms)

-

Bulk drugs & pharmaceuticals

Apart from the above, various innovative techniques for the industry.

| S.No | Name Of Cement / Power Plant | Location | Year | Details |

| 1 | Panipat Thermal Power Station Panfipat | Production Hall Modification | 2018/2019. | Air Cooling Plant |

| 2 | Raj West Power Limited Barmar Rajasthan. | Fire Door | 2017/2018. | 40 Nos Fire Door. |

| 3 | Raj Wet Power Limited | Fire Door | 2018/2019. | Fire Door 40 Nos. |

| 4 | Sanghi Cement | Panel Room Cooling | 2016/2017 | 300000 Cfm |

| 5 | M/S, Gujrat Ambuja, Himat Nagar, Ahmedabad | Air Cooling Panel Room | 2015/2016 | 200000 Cmh & 150000 Cmh |

| 6 | M/S, Gujrat Ambuja, Himat Nagar, Ahmedabad | Air Cooling &Ac | 2015 /2016 | 55000 Cmh |

| 7 | M/S, Benue Cement Comp-Ltd. (Man B & W Diesel Ltd., Nigeria Nachmo | Air Ventilation | 2013 /2014 | 100000 Cmh |

| 8 | M/S, Benue Cement Comp-Ltd. (Man B/W Disel Ltd Nigeria (Nachmo) | Air Ventilation | 2013 /2014 | 60000 Cmh 36 Nos |

| 9 | M/S, Sidhi Cement | Air Cooling | 150000 Cmh | |

| 10 | M/S, Sanghi Cement | Ventilation System For Pannel Room | 2014/2015 | 36,000 Cfm |

| 11 | M/S, C. Doctor & Co Pvt Ltd. (L&T) | Air Ventilation Oem | 2013 /2014 | 250000 Cmh |

| 12 | M/S, C Doctor For Bhel - Rajasthan Rajya Vidyut Utpadan Nigam Ltd. Suratgarh | Air Cooling Fabricated | 2016/2017 | 200000 Cmh. X 8 Set. Pre Fab |

| 13 | M/S, Saurashtra Cement Ltd Porbandar, Gujarat. | Air Cooling Plant | 30 000 Cfm Machinery Plant With Ducting | |

| 14 | M/S, Birla Corporation, Chandaria | Pre. & Ventilation | 2011/2012 | Pre Fab Ventilations |

| 15 | M/S, Birla Corporation, Chandaria | Pre. & Ventilation | 2011/2012 | 60000 Cmh X 3 Pre Fab Ventilations |

| 16 | M/S, Birla Corporation, Chandaria | Pre. & Ventilation | 2011/2012 | Including Ducting Work |

| 17 | M/S, Birla Corporation, Chandaria | Pre. & Ventilation | 2011/2012 | Pre Fab Ventilations |

| 18 | M/S, Birla Corporation, Chandaria | Air Cooling & Ventilation | 2011/2012 | 50 000 Cmh Pre Fab Ventilations |

| 19 | M/S, Birla Corporation, Chandaria | Air Cooling & Ventilation | 2011/2012 | Including Ducting Work |

| 20 | M/S. Saurashtra Cement Limited, Porbandar (Gujarat) | Dust Abatement | 2007 To 2012. | 40000 Cmh; 60000 Cmh X 2; 120000 Cmh X 2; 250000 Cmh |

| 21 | M/S, Gujarat Ambuja Export Utrakhand | Humidification Plant | 2012/2013 | 70000 Cmh Ahu |

| 22 | M/S, Gujarat Ambuja Export Hubali Kar Tak | Air Cooling Plant | 2012/2013 | 60000 Cmh Ahu 90 Tr. Dx |

| 23 | M/S, Sanghi Cement | Panel Room Ventilation | 2013/2014 | 65000 Cmh Ventilation |

| 24 | M/S, Sanghi Cement Limitd (Gujarat) | Air Cooling / Dust Abatement | 2013/2014. | 60000 Cmh X 1; 120000 Cmh X 1 |

| 25 | M/S, Birla Corporation, Chandaria | Pre. & Ventilation | 2011/2012 | Pre Fab Ventilations |

| 26 | M/S, Birla Corporation, Chandaria | Pre. & Ventilation | 2011/2012 | 60000 Cmh X 3 Pre Fab Ventilations |

| 27 | M/S, Birla Corporation, Chandaria | Pre. & Ventilation | 2011/2012 | Including Ducting Work |

| 28 | M/S, Birla Corporation, Chandaria | Pre. & Ventilation | 2011/2012 | Pre Fab Ventilations |

| 29 | M/S, Birla Corporation, Chandaria | Air Cooling & Ventilation | 2011/2012 | 50000 Cmh Pre Fab Ventilations |

| 30 | M/S, Birla Corporation, Chandaria | Air Cooling & Ventilation | 2011/2012 | Including Ducting |

| S No | Name Of Pharma Client | Detail | Year | Technical Detail |

| 1 | Accord Pharmaceticals. M.P. | Air Handling Unit. 3500 Cfm 9 Tr | 2016/2017 | 35000 Cfm 80 Tr |

| 2 | Voltas Ltd / Cadila Helth Care Bharuch Guj | Sa Hepa Box & R A Riser With Filter | 2016/2017. | 100 Nos. |

| 3 | Medwin Reserch And Helth Care Haryana | Onitment Mfg Plant 100 Kg | 2016/2017. | Onitment Mfg Plant 100 Kg |

| 4 | Voltas Ltd. Cadila Health Care Ankleshwar. Guj. | Hepa Box & Riser & Ducting | 2016/2017 | Hepa Box & Riser For Pharma |

| 5 | Regal Health Care Sikkim | Air Condensing With .03 Micron Filtration | 2016/2017 | 120 Tr Ahu 16 Nos. & Hepa & Ducting |

| 6 | Starling Biotech Ltd Baroda | Air Cooling | 2016/2017. | Ahu 20 000 Cfm |

| 7 | Horster Biotex Pvt Ltd. Indore, Mp | Pharma Project | 2017/2018. | 9 Nos. Ahu 1000/ 1500 /2000 / 3200 / 4700 / 3000 2900 1800 2100 Cfm |

| 8 | Voltas / Anlon Healthcare Pvt Ltd In Rajcot Guj. | Pharma Project | 2017/2018. | Ahu / Ducting / Hepa Riser |

| 9 | Suraj Health Essentials Bhiwandi | Pharma Machinery | 2017/2018. | Auto Single Head Bottle Capping |

| 10 | Voltas Ltd./ Cadila Health Care Unit-1 Ankleshwar | Production Aria | 2017/2018. | Riser & Hepa Box. |

| 11 | Jyoti Hospital Indoor Mp. | Operation Theatre | 2018/2019. | Ahu With Heap Box |

| 12 | Eta / Vadilal Hospital Ahmedabad. | 2018/2019. | Ducting Work | |

| 13 | Banaskantha Dist Co -Po Milk Prod Union Ltd. Palanpur | Air Condensing For Milk Filing Aria | 2018/2019. | Auh 35 000 Cfm 80 Tr. |

| 14 | Grv Health Care Haridwar | Pharma Machinery | 2018/2019. | Liquid Filling Auto Capping |

| 15 | Maa Chamunda Helth Care | Pharma Machinery | 2018/2019. | Liquid Filling Auto Capping |

| 16 | Nagar Pharmacy | Pharma Machinery | 2018/2019 | Liquid Filling Auto Capping |

| 17 | Cadila Helth Care / Voltas | Pharma Plant | 2018/2019 | Hepa & Riser |

| 18 | Sparsh Bio Tech Pvt Ltd / Voltas Ltd | Pharma Plant | 2019/2020 | Hepa & Risers |

| 19 | M/S, L & T Swich Gear (Snehal Ac&R Mumbai) | Air Cooling | 2006 /2007 | 1 00 000 Cfm X 5 Ahu |

| 20 | M/S, Cooling Air Solution | Ventilation | 2013 /2014 | 50 000 Cmh X 2 |

| 21 | M/S, C. Doctor & Co Pvt Ltd. (L&T) | Air Ventilation Oem | 2013 /2014 | 25 000 Cmh |

| 22 | M/S, Patel Air Temp Ltd Bhavnagar | Air Cooling | 2013 /2014 | 2 20 000 Cmh |

| 23 | M/S, Snehal Ac & R, Aurangabad | Air Cooling | 2013 /2014 | 150000 Cfm X 2; 75000 Cfm;3000 Cfm;5050 Cfm |

| 24 | M/S, Mother Dairy Bhat , Gandhinagar | Defreeze Room Modification | 2014/2015 | Modification |

| 25 | M/S, Subh Laxmi | Air Conditinons | 2014/2015 | 100 Tr |

| 26 | M/S, Blue Star Limited | Air Conditinons | 2014 /2015 | 170 Tr. 116 000 Cmh. Ahu. |

| 27 | M/S, Banas Dairy Bhat , Palanpur Gujrat | Air Conditinons | 2015/2016 | 270 Tr Civil |

| 28 | M/S, Subh Laxmi Poly | Air Conditinons | 2015/2016 | 60 Tr Ahu |

| 29 | M/S, Santi Proses Limited | Air Conditinons | 2015 /2016 | 40 Tr. Ahu. |

| 30 | M/S, Mother Dairy Bhat , Gandhinagar | Air Cooling | 2015/2016 | 850 Tr; 5 80 000 Cmh |

| 31 | M/S, Jayshree Polypro Ltd Gujrat | Air Cooling | 2015/2016 | 56 000 Cmh. Ahu |

| 32 | M/S, Banas Dairy Lakhnow Up | Air Conditions | 2016/2017 | 130 Tr; 90000 Cmh |

BRIEF PROFILE of FOUNDER Dr. VENKKATA SUDHIR L, M.E, Ph.D., F.I.E, M.I.S.H.R.A.E, C.E.A.,

A Post Graduate in Thermal Sciences (Energy Engineering) from College of Engineering Guindy [1989-90] with more than 25 years of experience in Energy Management. So far executed more than 250 Energy Studies in Various Industries in the country as well as abroad. He is presently advising many corporate houses for Sustainable Development projects & also closely working with Scientific committee of Annamalai in their Sustainable Development related research activities.

He was trained under DUPONT ENERGY MANAGEMENT DIVISION & was a Team member of UNDP-CII-MKRC project in 1992 worked along with International Energy Experts in Pulp & Paper, Petrochemical (Synthetic & Manmade Fiber), Textile, Engineering, Foundry, Automobile Industries. Thereafter for 2 years was heading the Energy Division of an upcoming Thermal Energy Company reporting to Managing Director. During this period, he was also trained in Design of Heat Transfer Equipment Design such as Economizer, Air Preheater, DE aerator, Flash Steam Recovery & Other Heat Recovery Systems.

In the year 1999 he started VSL PRAYAG ENERGY SYSTEMS & SERVICES in Chennai.

Since the year 2007, we started Manufacturing of Energy Efficient Equipment inclusive of Axial & Centrifugal Fans which find wide application in HVAC systems as well as Thermal Energy Saving equipment of various capacities. With the above systems, we have proven that it is possible to reduce the Energy Consumption by more than 25 to 35% as compared to the Conventional systems manufactured by conventional system suppliers. Dr. Venkata Sudheer L also developed Energy Efficient Air Conditioned Systems – Air Handling Units (AHU) as well as Centralised Air Conditioning Systems with the state of the Art Energy efficient systems inclusive of Close Loop system. These systems find application in Fiber Manufacturing Industries (Polyester etc.,) as well as in Clean Rooms AHUs in Pharmaceutical industries.

Over the past 11 years, VSLPRAYAG is associated with M/s. Samarth Airtech, Ahmedabad with Strategic Technology Partnership to manufacture Energy Efficient solutions (Humidification, Energy Efficient Axial flow Fans, Lighting systems & Automation systems for HVAC systems) as well as Heat Transfer Equipment. The AUTOMATION CONTROL SYSTEMS suitable for Temperature, Pressure, Flow, RH or any other parameter control – in Semi / Full Automation Systems with or Without SCADA systems. Application of Inverters (Variable Frequency Drives) is Optional for further smoother control of Fans or Pumps.

Mr. L Venkata Sudheer is a Certified Energy Auditor by Bureau of Energy Efficiency (since 2005). He is also a Chartered Engineer as awarded by The Institution of Engineers (India), Kolkata.

In the year 2008, Ministry of New & Renewable Energy (MNRE) appointed Mr. L Venkata Sudheer as a DISTRICT ADVISORY COMMITTEE for Chennai. The Term was for 3 years, which lasted up to 2011. This helped him in disseminating the information of use of Renewable sources of Energy across the State of Tamilnadu.

In the Year 2008, he has implemented Biomass gasification Project with Rice Husk for an MNC located in UP (M/s. OBEETEE Pvt. Ltd.,) which got them Carbon Credits apart from reducing the Power cost by 50%. They have issued us Certificate of Appreciation. Until 2014 - 15 they never depended upon UPSEB for all their Power Needs.

In August 2017, The Institution of Engineers (India) Kolkata, felicitated him & conferred Fellowship with the institution.